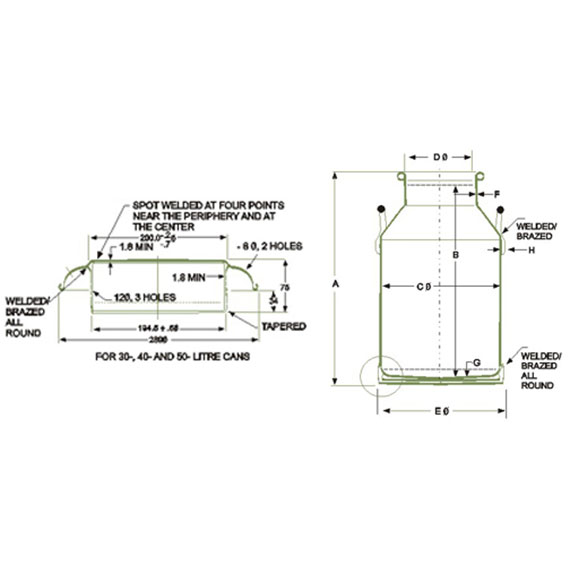

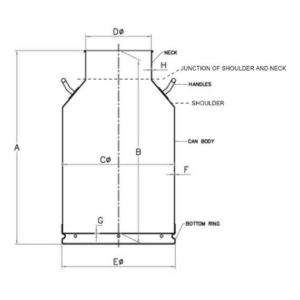

| (in liters) | A | B | CØ | DØ | EØ | F MIN | G MIN | H MIN |

| 20 | 447+/-4 | 431+/-3 | 280+/-3 | 200+/-0.5 | 292+/-3 | 1.6 | 2.0 | 2.5 |

| 30 | 512+/-4 | 496+/-3 | 320+/-3 | 200+/-0.5 | 332+/-3 | 2.0 | 3.0 | 2.5 |

| 40 | 591+/-4 | 575+/-3 | 340+/-3 | 200+/-0.5 | 352+/-3 | 2.0 | 3.0 | 2.5 |

| 50 | 651+/-4 | 634+/-3 | 360+/-3 | 200+/-0.5 | 372+/-3 | 2.0 | 3.0 | 2.5 |

Quality Control

Navkar is having its can as ISI certified by Bureau of Indian Standards (BIS) confirming to IS 1825-1983. Shri Navkar Metals Ltd strictly follows the procedures set and certified by Bureau Veritas Certification (India) Pvt Ltd. for internal management and production control and administration. Hence the organization is ISO 9001:2015 and ISO 14000:2015 Certified. Full-fledged ultra-modern laboratory equipped with all latest quality control equipment is working to ensure the pre-process, on the process, and post-process quality control measures to manufacture Aluminium Alloy milk cans. Drop Test, Hardness Test, and Leakage testes are thoroughly conducted before dispatch to ensure the strength and leackproofness.

Utility

Navkar Cans are used for transporting milk. Computer added monoblock design makes Navkar cans most suitable for transportation and transporting its contents safely, hygienically and without churning and spillage. Because of its hardness (85 BHN), Navkar Cans are tough and durable against rough use. Due to proper anodizng (15 micron and more) and using basically raw material from HINDALCO. Navkar cans are strong, smooth and thus are easy to clean and handle.

Aluminium Milkcan with Pull type Lid

Lockable Aluminium Milkcan